Small Vises - Limitless Potential

Workholding solutions optimized for high density and maximum utility.

-

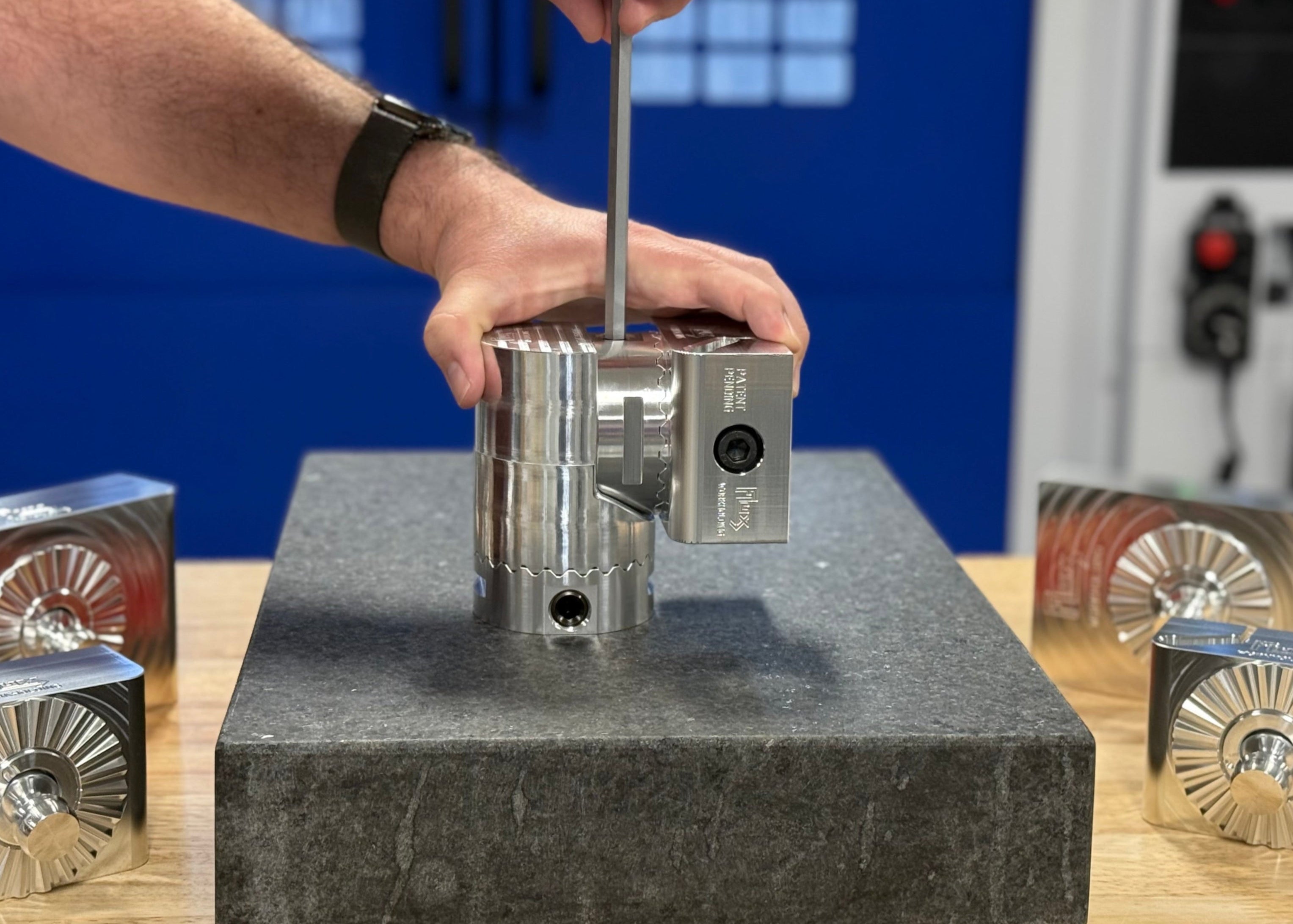

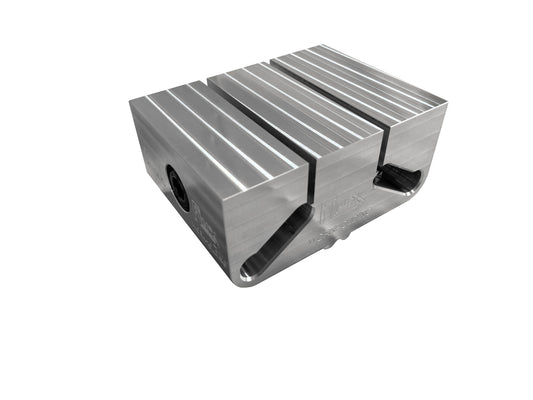

Quick Change Perfection

Best-in-class repeatability (<.0001 in) is achieved thanks to the game-changing Zero Clearance Coupling. Add and remove soft jaws in seconds, with zero struggle and 100% confidence.

-

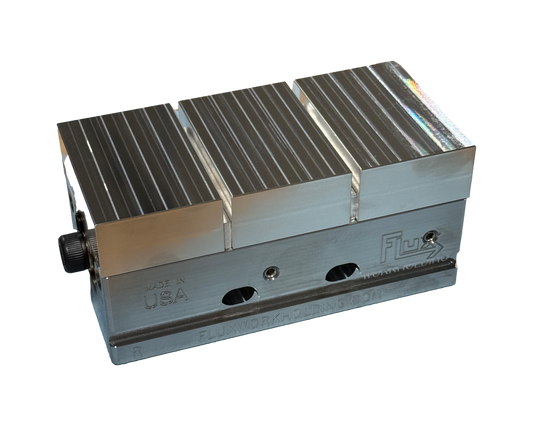

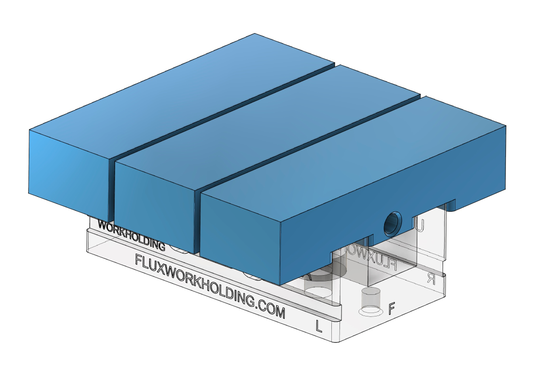

High Density Fixturing

Fit 4 times the number of parts in the same space as a traditional 6 inch vise, and watch productivity soar.

-

Less Screwing Around

1 screw secures 4 parts at a time for faster loading. Achieve part density on-par with a custom high-density fixture, but with less effort.

-

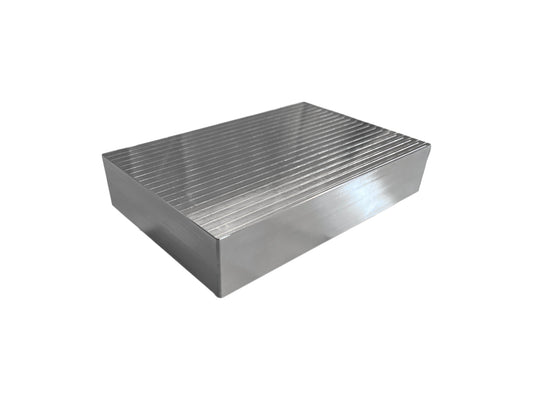

A Blank Canvas

The entire top surface is machinable. There are no cap screws to get in your way. Just choose the soft jaws that work best for the job at hand.

-

Made in the USA

All components are manufactured right here in the USA and ready to ship anywhere across the globe.

-

Modular Building Blocks

Vises and soft jaws are easy to re-use across families of parts. Your investment pays dividends long after the original job is done.

Featured products

-

Flux Vise - Starter Kit

Regular price From $494.00 USDRegular price -

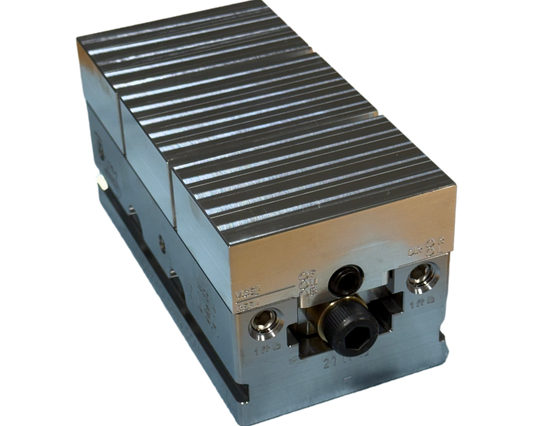

Flux Puck Starter Kit

Regular price From $275.00 USDRegular price$0.00 USDSale price From $275.00 USD -

Flux Puck 4th Axis Converter Kit

Regular price From $500.00 USDRegular price$0.00 USDSale price From $500.00 USD -

Dual Station Jaw Set - 6 Inch Width

Regular price $85.00 USDRegular price -

Flux Puck Single Station Vise 75mm X 100mm

Regular price $125.00 USDRegular price$0.00 USDSale price $125.00 USD -

Flux Puck Dual Station Vise 75mm X 100mm

Regular price $140.00 USDRegular price$0.00 USDSale price $140.00 USD